OCXOs (oven controlled crystal oscillators), sometimes referred to as temperature stabilized crystal oscillators or just crystal ovens, possess higher frequency stability, lower phase noise and wider operating temperature range when compared with TCXOs and common crystal oscillators. In particular, this frequency control device achieves the highest frequency stability possible with a crystal, making it suitable for satellite, electronic instrument, test equipment, mobile communication, broadcasting station, aerospace industry and other fields.

Working Principle

Our OCXO is mainly composed of a control circuit and an oscillator circuit, and the control circuit is designed to control the thermally-insulated oven while the other one is used to generate oscillation frequency. During working, the oven keeps quartz crystal at a constant temperature to minimize frequency variation which is often caused by ambient temperature change, and thermistors are employed to form a differential amplifier to control the temperature. In this way, oscillation frequency is maintained at a stable level.

Feature

1. High frequency, high precision, high frequency stability and fast warm up

2. Low phase noise, low power consumption, low supply voltage and low drive level

3. Wide operating temperature range

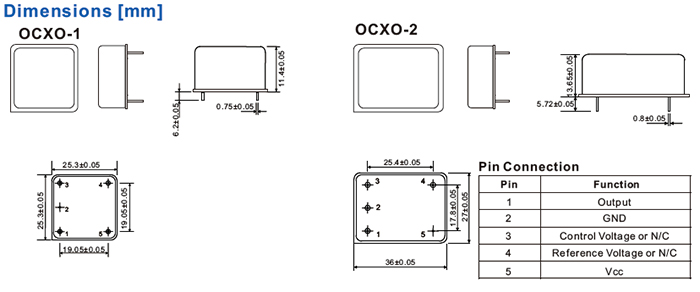

4. DIP14 package and DIP8 pacage

5. RoHS compliant and Pb-free

Application

1. OCXO works as a general crystal oscillator for various circuits to generate oscillation frequency.

2. It is a clock generator that works together with other electronic components to offer standard pulse signals for digital circuits.

3. It is also a quart crystal oscillator for MCU, CTV, VTR and watch.

Technical Data of OCXO

1. Crystal cut: SC/AT

2. Frequency range: 10MHz-100MHz

3. Operating temperature range: -40℃~+85℃

4. Frequency-temperature characteristic: 20ppb~100ppb (AT-cut), 5ppb~20ppb (SC-cut)

5. Supply voltage: +3.3V/+5.0V/+12.0V

6. Warm-up power: 5W

7. Output waveform: Sine wave

8. Size: 25×25×12mm (DIP8), 36×27×14 (DIP14)